What Are The 5 Best Types of Brushes For Latex Glove Manufacturing?

Latex gloves are used in many industries, such as healthcare and food processing. They are lightweight, disposable, and prevent bacterial contamination and infections.

Latex glove manufacturers use several industrial brushes in manufacturing to speed up the process of cleaning, coating, and beading the gloves. The brushes ensure the quality and consistency of the final product.

This article recommends 5 types of industrial brushes for latex glove manufacturing.

1. Washing Brushes

Washing brushes remove dirt, impurities, and residue from glove formers and machinery. Flexible nylon or PBT bristles are the best choice for thorough cleaning without damaging delicate surfaces.

Each washing brush fulfils a different purpose during the glove production process.

- Disc Brush

Large disc brushes wash and clean glove formers from the shank to the fingertips to remove chemical residue before re-dipping into latex solution. The formers typically pass between a pair of rotating disc brushes for washing.

- Flat Brush

Flat brushes can clean the shank and finger crotch parts of the glove formers. Large flat brushes have a wide, even surface area for extensive cleaning, while slimmer flat brushes are ideal for cleaning narrow spaces and crevices.

- Circular Brush

Large circular brushes wash the glove formers. Their long and flexible bristles can clean effectively between the fingers of the hand-shaped moulds. The individual pieces of circular brushes can be connected along the length of the shaft. It is convenient to install and can be easily replaced when the pieces are worn out.

2. Beading and Cuffing Brushes

- Circular Brush/Roller Brush/Spiral Brush

3. Stripping Brushes

Stripping brushes strip the gloves from formers after the latex dries. These brushes usually have nylon or PBT bristles, which are robust and flexible enough to remove gloves without damaging them.

- Circular or Roller Brush

After dipping, coating, and drying, the formers pass through rotating circular or roller brushes. The brushes’ revolving action pulls the gloves away from the mould.

The latex gloves are slipped off the formers and deposited onto a collection conveyor belt or bin below.

4. Track Cleaning Brushes

Track cleaning brushes with metal or nylon bristles are helpful for cleaning single and double former tracks. Regular oiling and cleaning are necessary for your machinery to operate smoothly. The track cleaning brush set may be installed by replacing the former holder set during offline maintenance to save time and labour cost.

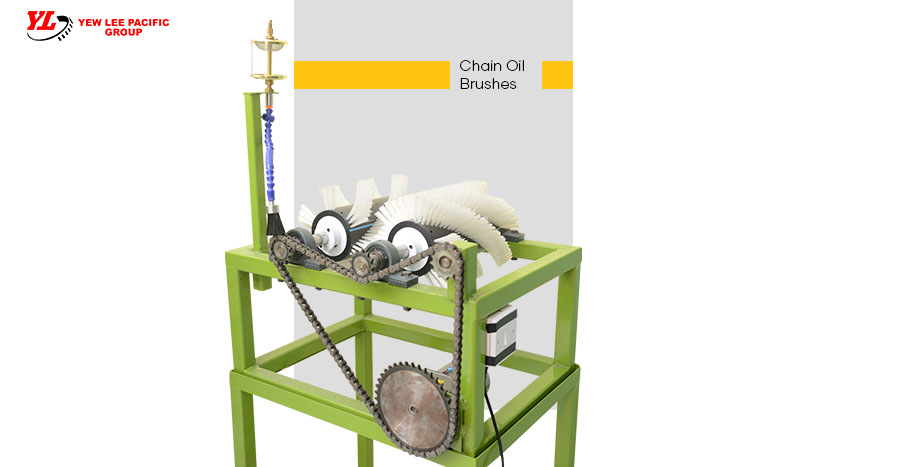

5. Chain Oil Brushes

The chain oil brush can be installed together with a glass can on the oil chain. It lubricates the oil chain during motion. It saves extra labour needed to apply lubricant on the oil chain during maintenance. This may shorten maintenance time and enhance productivity.

Conclusion

These 5 industrial brushes are essential to the latex glove production process. Washing, beading, stripping, track cleaning and chain oil brushes are required to ensure the gloves are high quality and adhere to hygiene and safety standards.

Yew Lee Pacific offers customised industrial brushes for latex glove manufacturing. We provide a range of brush fill patterns, bristle materials, and brush sizes to suit all your needs.

In addition to the industrial brushes, Yew Lee Pacific also offers a wide variety of industrial hardware and machinery parts for installation on production lines. Our product range includes rubber, plastic and steel pipes, fittings, flanges, valves, and much more.

Contact us to discuss your industrial brush and machinery parts requirements!