Custom vs Standard Industrial Brushes: When Should You Invest in Custom Designs?

When sourcing industrial brushes, many buyers face the same question: Should we use standard off-the-shelf brushes, or invest in custom-designed industrial brushes?

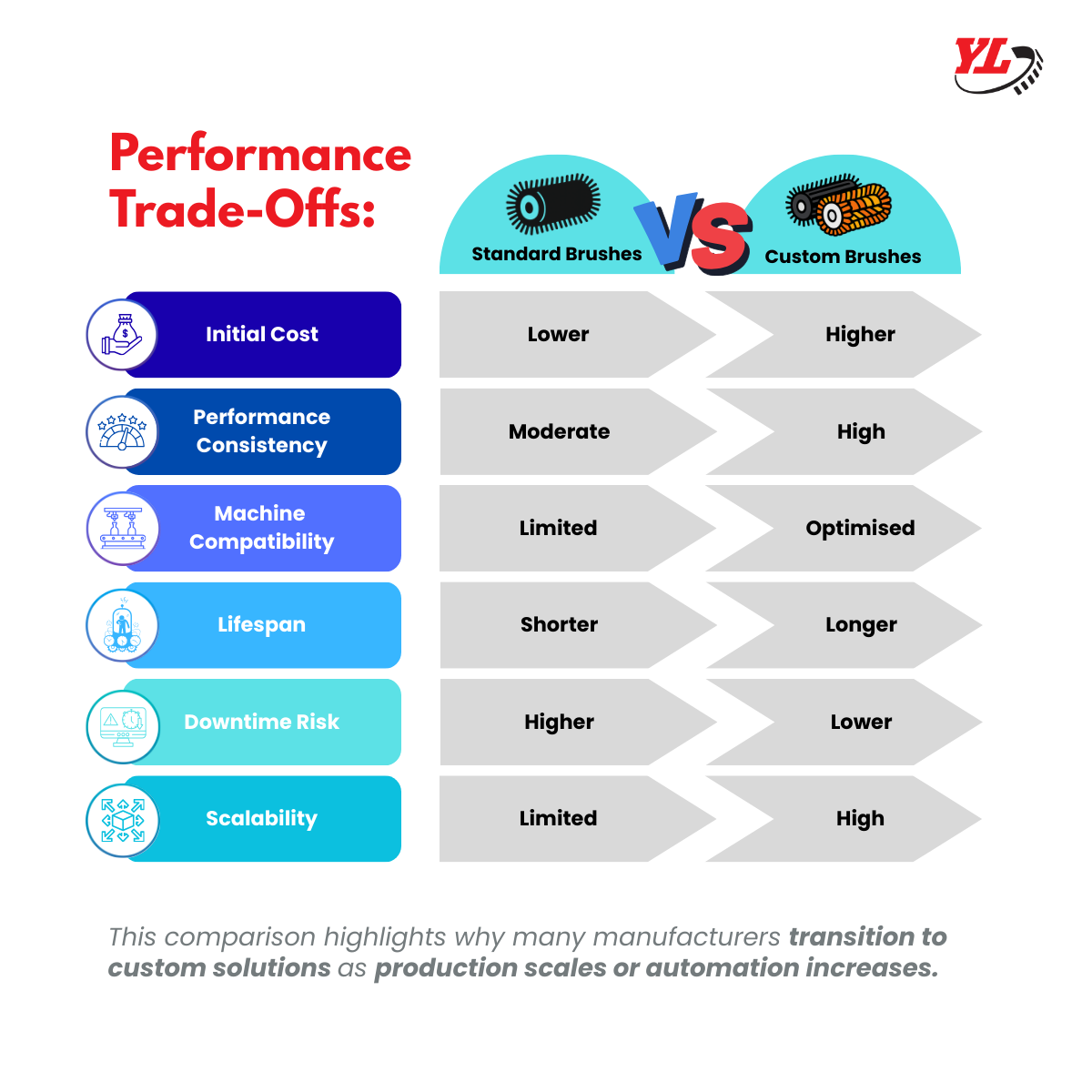

The answer is not always straightforward. While standard brushes may appear more cost-effective upfront, custom industrial brushes often deliver better performance, longer lifespan, and lower total operating costs — when applied to the right situations.

This article breaks down the decision from both an engineering and cost-justification perspective, helping manufacturers, engineers, and procurement teams make informed choices.

What Are Standard Industrial Brushes? (Definition, Pros & Limitation)

Standard industrial brushes are mass-produced brushes with fixed specifications. They are typically available in predefined sizes, materials, bristle densities, and mounting options.

Advantages of Standard Brushes

- Lower initial purchase cost

- Shorter lead time

- Suitable for basic or non-critical applications

- Easy replacement and availability

Considerations When Selecting Standard Brushes

- Best suited for standardized machine designs and common setups

- Offered in widely used bristle materials and stiffness ranges

- Performs optimally when matched to recommended applications

- Ideal for predictable operating conditions and routine processes

Standard brushes work best when operating conditions are predictable, tolerances are forgiving, and performance requirements are modest.

What Are Custom Industrial Brushes? (Design, Materials & Customization Options)

Custom industrial brushes are engineered based on specific machine parameters and operating conditions. Instead of forcing a standard brush to fit a process, the brush is designed to fit the process from the start.

- Customisation may include:

- Bristle material selection

- Bristle trim length, stiffness, and density

- Brush diameter, length, and core material

- Brush pattern (straight, spiral, V-pattern, staggered)

- Mounting methods and shaft tolerances

Custom brushes are commonly used in continuous production lines, automated systems, and applications where consistency and reliability are critical.

Engineering Perspective: Performance, Compatibility & Machine Fit

Machine Fit and Contact Efficiency

A brush that is not dimensionally optimized may result in uneven contact pressure, vibration, or incomplete cleaning. Custom brushes are designed to match:

Conveyor width and speed

Contact force requirements

Product surface geometry

This improves cleaning consistency while reducing mechanical stress on equipment.

Bristle Behaviour Under Load

Bristle material and stiffness determine how a brush behaves during operation. In standard brushes, bristle properties may be unsuitable for:

- High-speed rotation

- Fragile surfaces

Heavy debris or compacted residue

Custom brushes allow precise tuning of bristle behaviour, improving performance without over-aggressiveness.

Cost Perspective: Upfront Price vs Total Cost of Ownership (TCO)

Initial Cost Comparison

Standard Brushes: Lower upfront cost

Custom Brushes: Higher initial investment due to design and tooling

However, focusing only on purchase price often leads to higher long-term costs.

Long-Term Cost Factors Often Overlooked

Custom industrial brushes often reduce:

Replacement frequency

Machine downtime

Maintenance labour

Product rejects caused by inconsistent cleaning or finishing

When evaluated over time, the total cost of ownership (TCO) for custom brushes is frequently lower than repeated replacement of standard brushes.

When Standard Industrial Brushes Make Sense

Standard brushes are suitable when:

Production volume is low

Applications are non-critical

Equipment tolerances are flexible

Budget constraints are strict

Temporary or trial operations are involved

They are often a good starting point for early-stage production or non-specialised tasks.

When Custom Industrial Brushes Are the Smarter Investment

Custom brushes are recommended when:

Production lines operate continuously or at high speed

Downtime carries high operational costs

Surface quality must meet strict specifications

Brushes interact with automated systems

Standard brushes wear too quickly or perform inconsistently

In these scenarios, custom brushes function as engineered components rather than consumables.

How to Evaluate ROI Before Investing in Custom Industrial Brushes

Before committing to a custom solution, consider:

Current brush lifespan and replacement frequency

Cost of downtime per hour

Maintenance labour involved

Product rejection or rework rates

Expected performance improvements

Comparing these factors provides a clearer justification beyond upfront pricing.