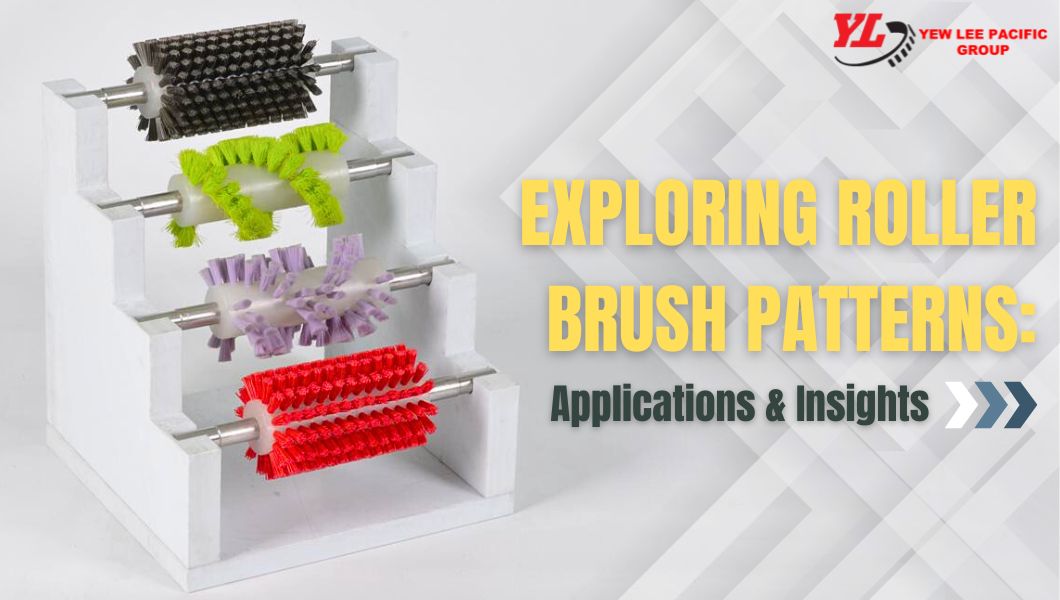

Roller brushes are versatile tools widely used across different industries, from cleaning and polishing to coating and surface finishing. The arrangement of the bristles on the roller, known as the brush pattern, can significantly impact the performance and effectiveness of these brushes.

In this blog, we’ll explore the differences between four common roller brush patterns—V-pattern, spiral, straight, and full staggered—along with their specific functions and best applications.

1. V-Pattern Roller Brush

The V-pattern roller brush features bristles arranged in a V shape along the length of the roller. This pattern concentrates the brushing action towards the center of the brush. It excels in situations where precision, deep penetration, and focused cleaning are required.

Key Characteristics:

- Targeted Cleaning: The V-pattern focuses pressure towards the center, making it ideal for working on surfaces that require precise brushing.

- Good Agitation: The concentrated action helps lift particles, dirt, or debris, making it effective for thorough cleaning tasks.

2. Spiral Pattern Roller Brush

A spiral pattern roller brush has bristles arranged in a helical pattern around the roller’s core. This arrangement creates a sweeping motion as the brush rotates. It enhances its ability to minimize streaks, resulting in consistent and thorough brushing.

Key Characteristics:

- Continuous Brushing Action: The spiral pattern provides a constant brushing motion, ensuring that every surface area is brushed evenly.

- Gentle Sweep: The sweeping action is ideal for applications where a smooth, gentle finish is required.

3. Straight Pattern Roller Brush

The straight pattern roller brush is the simplest design, with bristles aligned parallel to each other along the length of the roller. It’s the go-to choice when simplicity, even coverage, and affordability are the top priorities.

Key Characteristics:

- Consistent Pressure: The parallel arrangement of bristles ensures that pressure is applied uniformly across the entire width of the brush.

- Simplicity and Versatility: Its basic design makes it easy to use and adaptable to various types of bristle materials.

4. Full Staggered Pattern Roller Brush

The full staggered pattern roller brush features bristles arranged in a staggered formation, where rows of bristles are offset from each other. This pattern ensures that no part of the surface is left untouched, making it ideal for heavy-duty cleaning or tasks where complete surface coverage is necessary.

Key Characteristics:

- Maximum Coverage: The staggered arrangement ensures that the bristles cover every inch of the surface as the brush rotates.

- High Efficiency: The offset bristles prevent clumping or buildup, allowing for smooth brushing action and more efficient debris removal.

Comparing the Brush Patterns: Which One Is Right for You?

| Brush Patterns | Best For | Pros | Cons |

|---|---|---|---|

| V-Pattern | Grooved or detailed surfaces | Precise, targeted cleaning | Not ideal for even applications and flat surfaces |

| Spiral | Smooth, cylindrical objects | Consistent, gentle brushing | Less aggressive for deep cleaning |

| Straight | Flat, uniform surfaces | Simple, versatile | May miss areas on uneven surfaces |

| Full Staggered | Heavy-duty and complete coverage tasks | Maximum coverage, efficient | More complex, potentially higher cost |

Conclusion

In conclusion, understanding the differences between various roller brush patterns, along with their respective pros and cons, is essential for selecting the most suitable option for your needs. This careful selection ensures that you achieve optimal performance, efficiency, and durability in your specific application.

While different brush patterns may serve the same function such as cleaning or sorting, the best choice ultimately hinges on specific requirements, system designs, and the characteristics of the materials involved.

Moreover, utilizing different brush patterns together can complement each other, enhancing overall process effectiveness. By making informed decisions based on these insights, businesses can significantly improve operations and achieve better results.

For more information about roller brushes, you may visit the blog – What Are Industrial Roller Brushes Used For?

Please contact us if you would like to speak with our brush specialist.