Different types of bristle materials have their own characteristics such as hardness, thermal resistant, water absorption, chemical resistant and etc. The main consideration in designing a brush is the actual applications and uses of the brush.

Besides the type of bristle materials, the diameter of the individual bristle, the trim height of bristle, the diameter of bristle bundles and the distance between bristle bundles can be varied. All these factors have a bearing on the eventual hardness or softness of the brush.

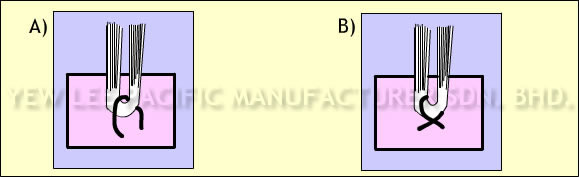

Stapling provides consistent product quality and reliability. Below illustrations show the difference between the two types of stapling process. The crossover staple has greater tuft retention strength then the straight staple. Straight stapling (A) is the typical outmoded technology in brush manufacturing. Crossover stapling (B) is achieved by YLPM by using the most advance state-of-art Italian technology.

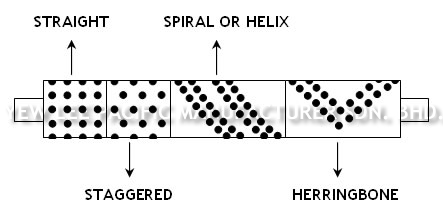

Brush Fill Terminology also play an important role in the process of designing a brush. The application, kind of product, direction and the speed of turning will directly influence the designing of the Brush Fill on a brush. The brush shown in the illustration below shows the various modes of Brush Fill.