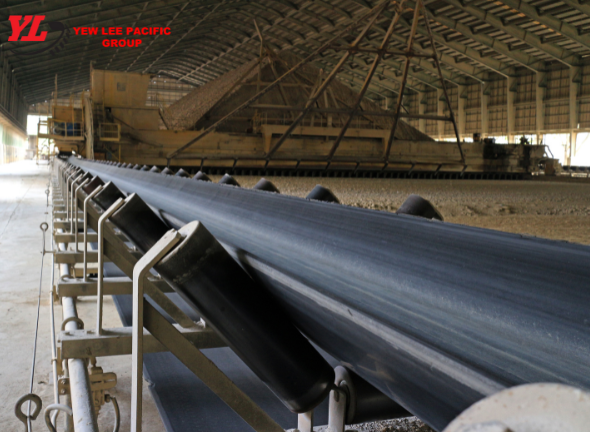

Conveyor systems are at the heart of many industrial operations, from manufacturing plants to food processing facilities. They provide the backbone for transporting materials and goods, offering efficiency and reliability in handling large volumes of products.

While the focus often falls on the conveyor belts themselves, the components that maintain the system’s smooth operation, like conveyor brushes, are equally crucial.

In this blog, we will explore the uses of brushes in conveyor systems, and the different ways they contribute to the efficiency.

What is a Conveyor Brush?

A conveyor brush is a specially designed brush used in various types of conveyor systems. It serves multiple purposes depending on the industry and the specific needs of the system.

These brushes are mounted along the conveyor belt or integrated into other parts of the system to perform different cleaning, guiding, and maintenance tasks. Conveyor brushes can be found in a variety of configurations—such as strip brushes, flat brushes, roller brushes or spiral brushes—and are made from different materials to suit specific applications.

Key Uses of Conveyor Brushes

1. Cleaning the Conveyor System

One of the primary uses of conveyor brushes is for cleaning. Conveyor belts often accumulate dirt, dust, grease, oil, or debris during material transport. If left unaddressed, this buildup can affect the efficiency of the system, leading to poor product quality, delays, or even system breakdowns.

Brushes mounted along the conveyor belt remove particles and contaminants from the surface. This helps prevent material contamination, ensuring the cleanliness of the product being transported.

2. Preventing Product Contamination

In industries like food processing or pharmaceuticals, cleanliness is critical.

Conveyor brushes help prevent the contamination of products by removing debris and particles that could taint the items being moved. For example, in a food processing plant, even small pieces of material stuck on the conveyor could end up in the products being transported, resulting in quality issues or even health risks.

In some cases, specialized brushes made from food-safe materials are used to ensure hygiene standards are met while maintaining the conveyor’s operational efficiency.

3. Product Orientation and Alignment

Conveyor brushes can also serve to guide and align products as they move along the conveyor.

In high-speed applications or when transporting irregularly shaped items, the brush can gently nudge the products into proper alignment for subsequent operations like sorting, packing, or inspection., preventing jams and facilitating efficient handling.

4. Preventing Static Buildup

In some industries, particularly those dealing with plastics, rubber, or electronics, static electricity can be a major concern.

Conveyor brushes made from static-dissipative materials can help reduce or eliminate the buildup of static charges, preventing damage to sensitive electronic components or reducing the risk of sparks that could lead to fires or explosions in hazardous environments.

5. Extending Conveyor Belt Life

Conveyor brushes also play a role in extending the lifespan of the conveyor belt. By preventing the buildup of material on the belt, they help reduce friction, which in turn minimizes wear and tear.

Moreover, cleaning the belt regularly helps maintain its tensile strength and functionality. Brushes remove abrasive particles that could damage the surface of the conveyor belt, thus enhancing its durability and reducing the need for frequent replacements.

Conclusion

Conveyor brushes are indispensable components in modern conveyor systems, offering vital cleaning, maintenance, and operational benefits. Whether it’s cleaning debris, preventing product contamination, or extending the life of the conveyor belt, these brushes contribute to the smooth functioning of industries across the globe.

As industrial operations continue to scale and become more complex, the role of conveyor brushes in ensuring efficiency, safety, and product quality will only grow more essential. Whether you’re in manufacturing, food processing, or any other industry that relies on conveyor systems, investing in the right brushes can make a significant difference in maintaining the health of your equipment and the quality of your products.

Contact us if you want to know more about conveyor brushes.