How To Choose Suitable Metalworking Industrial Brushes?

Metalworking is a heavy-duty, global manufacturing industry that requires precision, quality, and robust tools. Industrial brushes are a critical part of the metal manufacturing process. These brushes are available in different sizes and materials for specialized tasks like weld deburring, polishing, cleaning, and rust removal.

Selecting the best brushes for your manufacturing processes can be challenging with so many options. This blog provides tips for choosing suitable brushes and recommends 4 types of brushes for metalworking industries.

5 Things to Consider For Metalworking Industrial Brushes

Before deciding the type of industrial brush you want, consider these 5 things:

1. Metal Type

When working with stainless steel, you need softer bristles than carbon steel. You need a robust brush to remove unwanted material. The bristles should be soft enough to avoid scratching the surface.

2. Brush Size

The metal surface area you work on determines your desired brush size. Small brushes are ideal for working on detailed or hard-to-reach parts. Larger brushes are suitable for larger metal pieces.

3. Bristle Material

Metalworking requires brushes with different bristle types for different manufacturing stages. For instance, cutting and deburring usually require more robust metal bristles like steel or abrasive nylon. Softer brass bristles are better for delicate applications like polishing and finishing.

The 4 most commonly used bristle materials in brushes for metalworking industries are:

Steel: Deburring, cutting, polishing, and removing rust and paint from metal surfaces.

Brass: Gentle polishing and deburring and is ideal for softer metals.

Nylon: Finishing and polishing processes.

Abrasive: Surface finishing, polishing, and deburring.

Need more information on bristle types? You can refer to our previous blog on choosing suitable materials for industrial brushes.

4. Speed and Power Requirements

Different metalworking brushes have different speeds and power requirements. Using too much speed and power on a low-requirement brush causes bristles to wear out faster. Likewise, using a brush with high speed and power requirements on a slower machine could strain and damage your equipment over time.

Choose a brush type compatible with your equipment’s speed and power output to avoid damaging the brush or machinery.

5. Brush Shape

Metalworking brushes come in different shapes. You can choose circular disc brushes, narrow hand brushes, or long roller brushes.

Ensure your brush shape is suitable for the application type. Flatter disc brushes have a large surface area and are ideal for polishing, finishing, or removing paint and rust. Smaller circular or roller brushes are suitable for cleaning corners and hard-to-reach areas.

4 Types of Industrial Metalworking Brushes

By considering the metal type, brush size and shape, bristle material, and power requirements, you can choose the right brushes for metalworking industries to optimize your metalworking processes.

This section introduces the 4 useful types of industrial metalworking brushes.

1. Circular Brushes

Metalworking circular brushes usually have abrasive nylon or metal bristles. These robust and durable brushes are ideal for cleaning, deburring welded parts, polishing metals, and removing rust, corrosion, or paint from metal surfaces.

Abrasive nylon bristles contain abrasive additives like silicon carbide, ceramic, or aluminum oxide for extra grit. These brushes are suitable for polishing and cleaning softer metals like aluminum and brass or harder metals like steel and titanium. The flexible bristles fit around contours and edges for maximum brushing coverage.

Abrasive metal bristles help with heavy-duty cutting, deburring, polishing, edge blending, surface finishing, and removing rust or heat discoloration. Metal bristles are stiffer and more robust than abrasive nylon bristles, so they are suitable for aggressive brushing.

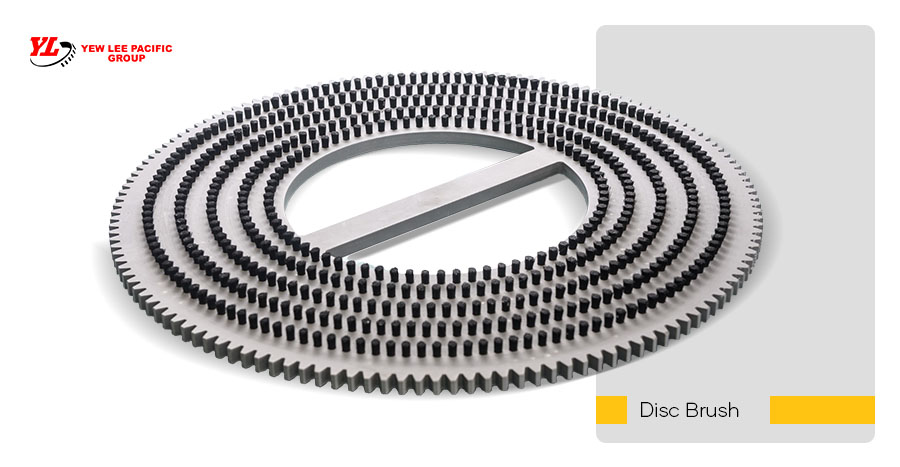

2. Disc Brushes

Disc brushes have a broad surface area for application. They polish and clean broad surface areas or corners.

You can also use them for rust and paint removal from metal surfaces, weld deposit cleaning, and deburring.

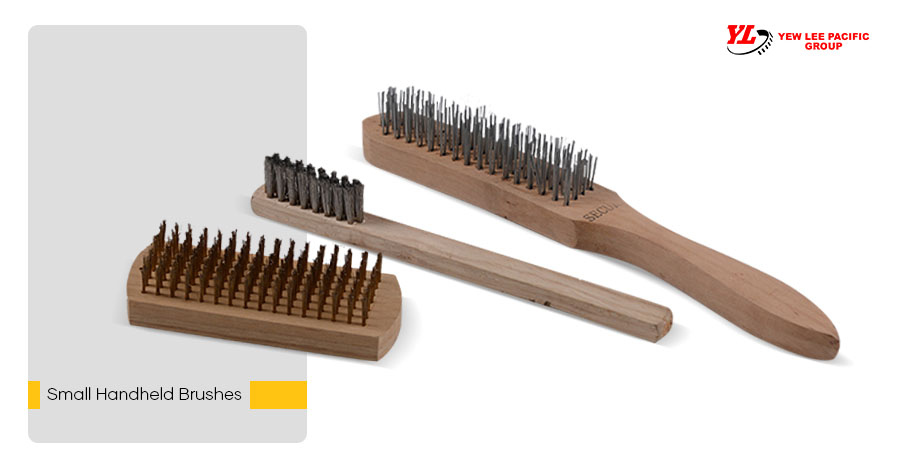

3. Small Handheld Brushes

Small handheld foundry brushes help clean tight, narrow spaces and hard-to-reach areas. They have robust steel wire bristles for durable cutting and deburring applications.

Use them for scrubbing, deburring, and removing rust from small steel and ironwork pieces, such as screws and bolts.

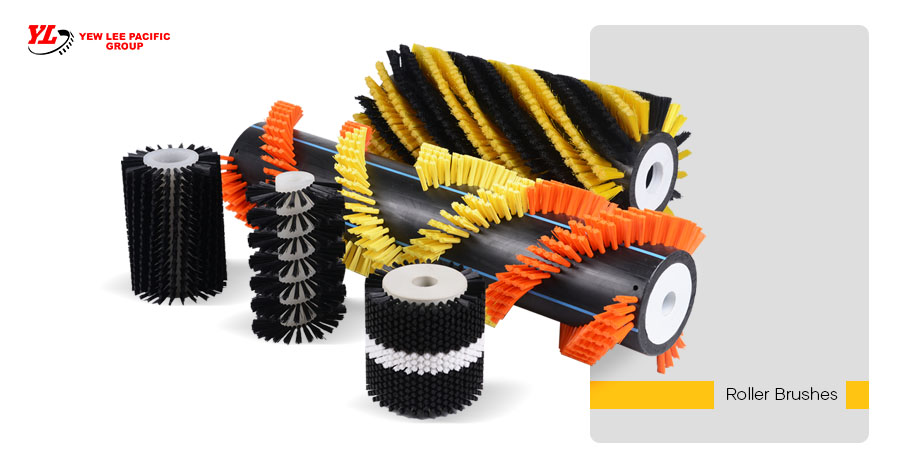

4. Roller Brushes

Metalworking roller brushes have abrasive nylon or metal bristles. You can choose from a range of tuft patterns for different cleaning needs. For more information about roller brush tuft patterns, read our previous blog about different types of industrial roller brushes.

Metalworking roller brushes are ideal for removing rust, paint, corrosion, and finishing or polishing metal surfaces. Use softer brass bristles or abrasive nylon for gentler polishing and cleaning. Consider an abrasive and durable bristle material like steel for heavy-duty work.

5. Custom-Made Brushes

Yew Lee Pacific is also in the process of producing more specialized brush types for metalworking industries. Some examples are cup brushes, wire wheel brushes, and end brushes for installation on machinery.

We consider the quantity, demand, and availability of OEM manufacturers when producing new brush types. Contact us with your brush requirements to discuss a solution!

Conclusion

Choosing the best metalworking industrial brush depends on multiple factors. You should consider the metal surface type, brush size and shape, bristle material, and brush power requirements.

The best options are circular brushes, disc brushes, small handheld brushes, and roller brushes. They are versatile, robust, and suitable for specialized or general tasks. Select suitable industrial brushes to ensure your metal manufacturing processes and products are efficient, precise, and high-quality.