Industrial roller brushes are also known as cylinder brushes. They are a highly versatile and popular kind used in many manufacturing processes and industries.

Roller brushes are commonly used for cleaning and sweeping large or uneven surfaces, polishing, finishing, and dusting. You can use them for general cleaning of floors and work surfaces. You can install them on machines to clear conveyor belts, descale processing lines, and clean treated objects. Or, use their fine bristles to gently sort and move small items. You can use roller brushes for a range of tough and delicate cleaning or sorting operations.

Do you want to buy industrial roller brushes for your manufacturing process? You may be looking for more information on roller brush functions and designs to help you decide better. This article will explain the different materials, types, and common uses of industrial roller brushes. So stick till the end!

Materials

Roller brushes usually made in plastic rods or pipes that can be directly installed onto the shaft or supplied as loose pieces to fit on existing shafts. Yew Lee Pacific can drill the diameter of the brush core or arbor hole to a custom size.

Roller brushes with a metal shaft and a solid body (plastic rods) have high load torque to withstand attachment to machinery or spinning motors. You can best use them for aggressive brushing to polish or clean materials and surfaces. For gentler cleaning, you can choose hollowed (plastic pipes) roller brushes with a lighter fill density. You can also change the toughness of the brush fill by selecting soft or hard brush monofilaments. This type of roller brushes are suitable for food processing, agricultural washing, glassmaking, and printing industries.

The tuft alignment can be continuous or divided into spiraled or conical segments based on custom specifications. Other tuft patterns, such as helix and chevron designs, are also available for different cleaning needs. Yew Lee Pacific can staple or hand-draw the fill material into the brush core accordingly.

When you customize your roller brushes, pick core and monofilament materials that best suit the brush function. You can choose the most suitable monofilament material from Yew Lee Pacific’s wide collection of high-quality synthetic and metal materials. Vary your choice of monofilament material with the type of surface you are cleaning.

If you need roller brushes for aggressive cleaning, polishing, or deburring. Consider an abrasive, durable monofilament material like steel in that case. Metal monofilaments are ideal for heavy-duty cleaning. For gentle polishing, consider a softer brass monofilament material. A synthetic core with softer bristles is more suitable if you use the roller brush for dusting or sorting objects. Conductive monofilament materials like antistatic nylon are best for cleaning sensitive electrical components.

Types Of Roller Brushes

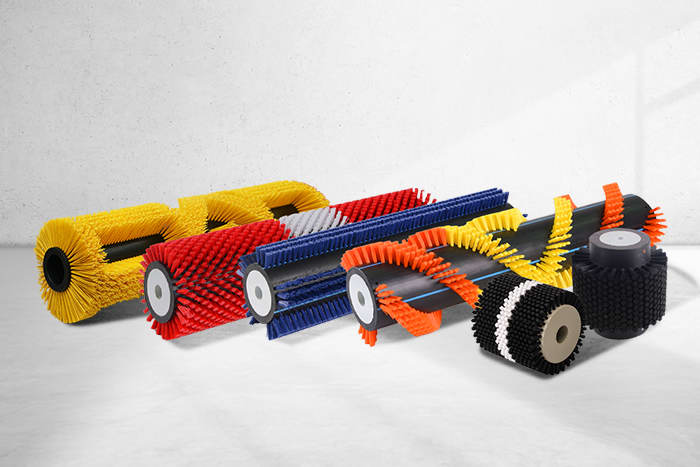

Yew Lee Pacific produces roller brushes of all sizes, fill densities, core shaft diameters, and trim lengths. Now you will read about some of the most common industrial roller brush types and their uses.

Tufted Roller Brushes

Tufted roller brushes are the most common and widely-used roller brush type. They are made by stapling knotted filaments into cores. They are highly versatile and adaptable because there are many variations in fill density and tuft patterns. The most common tuft patterns are straight, spiral or helix, staggered, and herringbone.

Tuft materials are usually machine-stapled or hand-drawn into the brush core according to the specified pattern and fill density.

Tufted roller brushes are ideal for powdering, dusting, pressure-cleaning, sweeping, transporting, and washing.

Sweeping Roller Brushes

You may use sweeping roller brushes in large areas like pavements, warehouses, yards, and factory floors. Sweeping roller brushes are suitable for clearing dirt, leaves, sand, and mud. You can use sweeping brushes with water spray systems for more rigorous cleaning.

Yew Lee Pacific offers a range of durable fill materials and patterns for your sweeping brushes. We recommend choosing durable and waterproof monofilament material for sweeping brushes because you may use the brush in harsh outdoor environments. Synthetic nylon or polybutylene terephthalate (PBT) is ideal for outdoor use. It is because these materials can resist strong impact, chemicals, and wet conditions.

Beading Roller Brushes

Yew Lee Pacific also makes beading brushes catered explicitly to the latex glove manufacturing industry. Latex glove manufacturers use beading brushes to create the beading cuff roll on manufactured latex and surgical gloves.

Other types of roller brushes are also used in latex glove manufacturing. Glove manufacturers their large tufted kind for cleaning and de-molding gloves during production. They may also use rotating tufted roller brushes to wash the hand molds before re-dipping them into latex solution.

Customize Your Ideal Industrial Roller Brush With An Experienced Brush Manufacturer

This blog introduced you to different roller brushes used in industrial manufacturing. They are versatile and valuable in many industries. They streamline the cleaning process and can be custom-made to fit any machine and cleaning area. It makes them a popular industrial brush type that you can consider for your business.

Yew Lee Pacific can make customized roller brushes according to your needs and specifications. We provide a range of brush sizes, trim lengths, monofilament materials, and fill densities. Customize your roller brush by filling in our online form, and we’ll contact you to understand the specifications you want. Let us know your requirements, and we’ll create high-quality brushes that best suit your cleaning needs.