Industrial brushes are unique and essential tools in manufacturing. They are highly versatile, adaptable, and used in several industries for various purposes. An industrial brush’s work surface consists of thousands of filaments for cleaning, cutting, or polishing. Monofilaments – or bristles, may be made of natural, metal, or synthetic materials, depending on the work surface needed.

Industrial brushes come in many shapes and designs for different functions. Some are connected to motors for heavy-duty work, like polishing and cleaning glasses and wood in manufacturing. Other brush types clean conveyor belts or floors, and smaller brushes clean irregular machine parts and technical equipment. Depending on the manufacturing process and customer needs, industrial brushes can also be custom-made.

Choose Right Industrial Brushes For Your Business

With so many industrial brushes available, you will need to learn how to choose the best brush for your business. This article explains the uses of some of the most popular industrial brushes available near you. It also compiles lists of the common industries that use these brushes. Understanding brush functions and customization options are essential to select the best type of brush for your production processes.

Roller Brushes

Roller brushes, also known as cylinder brushes, are one of the most widely used brush types in industrial manufacturing. They are available in many sizes, materials, densities, core shaft diameters, and trim lengths.

The most common uses of roller brushes are floor cleaning, sweeping large or uneven surfaces, polishing, finishing, and dusting. Roller brushes are installed on conveyor belts and factory process lines to clean surfaces or move smaller items. You can use them in latex glove beading, descaling of processing lines, and gentle sorting of small objects. They function well in many tough and delicate manufacturing processes, as you can customize them for different purposes.

The tufts alignment can be continuous or divided into spiraled and conical segments based on custom specifications. Most roller brushes fitted on industrial machines are motor-driven with metal shaft and can withstand high load torque. When customizing the brush, consider the core and bristle material best suits your cleaning surface.

Circular Brushes

Circular brushes are available in many sizes, bristle materials, densities, and trim lengths. Depending on your needs, you can customize them to contain hybrid filaments or alternating sections with different filament types.

Circular brushes are commonly used for washing and cleaning objects and surfaces. They are also used for de-rusting, deburring rough edges, and descaling lime and paint. Interestingly, many industries use circular brushes, including latex glove production, woodworking, and food processing. Consider larger circular brushes for polishing or washing and smaller circular brushes for cleaning hard-to-reach crevices or irregular surfaces. They may be used for beading in latex gloves, deburring of welding in metalworking, and paint stripping in construction.

Lath Brushes

Lath brushes are widely-used industrial brushes and come in a slim, elegant shape and style, making them versatile. They are also easy to assemble and mount on machinery.

A lath brush is a rectangular or square-handled brush with bristles. Based on customization requirements, Yew Lee Pacific usually makes a handle from wood, plastic, or metal. Monofilaments come in various fill materials and can be customized based on the brush’s function.

Lath brushes are usually attached to the manufacturing machinery or assembly line structure for cleaning. They also clean and descale objects after treatment processes and clear loose materials. They are also helpful for the delicate cleaning of flat surfaces, like smoothing creases in paper production and dusting glass. Lath brushes with fine bristle materials can be used as a base to transport fragile items. They are also used to close gaps in machine centers.

Due to their versatile functions for cleaning different surfaces, transporting objects, and sealing openings, several industries use them.

Disc Brushes

Disc brushes consist of a round block with monofilament material stapled parallel or slightly angled to the core axis. What Yew Lee Pacific usually does is drill an arbor hole in the handle block for mounting or affixing to machinery. You can customize the monofilament fill material based on cleaning purposes. You can also customize the diameter of the brush and the arbor hole to fit different structures.

Disc brushes are primarily used for heavy-duty cleaning, sweeping, polishing, and scrubbing. Many industries use them as a scrub brush, including commercial cleaning. Interestingly, metalworking industries use them for deburring welded metals, while landscaping and construction industries use them for removing weeds.

Twist Brushes

Twist brushes are also known as spiral, tube, bottle, or flue brushes. They consist of monofilament material and metal wire cores. The metal wire stem is bent doubled-over, and bristles are inserted between them and twisted to be secured.

Yew Lee Pacific can insert fill material on one end, both ends, or in the middle of the brush. Monofilament materials are made of natural, metal, or synthetic materials. The fill position and monofilament material can be customized based on your needs.

Twist brushes come in different shapes other than the regular rounded brush head. Yew Lee Pacific can trim the bristles to create conical, concave, convex, tapered, rectangular, or square brushes, depending on the function.

You can use smaller twist brushes to clean test tubes, pipes, and bottles in laboratories or commercial kitchens. You may customize a long handle to affix a thin twist brush to a power tool for deep cleaning. It helps clean hard-to-reach machinery parts or clears hardened residue. The automotive and aviation industries also use twist brushes for cleaning hydraulic and engine parts.

Spiral Brushes

Spiral brushes usually begin as straight strip brushes with metal backings. The strip is then wound on a core or shaft to bend the brush into a spiral or cylindrical shape. Yew Lee Pacific can vary the spacing between the coils for a wide range of fill densities.

The most common type of spiral brush has outward-pointing filaments. They are regular cylindrical brushes that are stretched to the required length. They are then mounted on a shaft, and the bristles work as the brush rotates. You can vary monofilament densities for denser or lighter fills, which are suitable for heavy-duty or gentle cleaning, respectively.

Spiral brushes are also used in latex glove beading, cleaning glass, sanding wood and clearing debris from abrasive blasting. You may also use them for descaling and cleaning objects after treatment processes in product manufacturing. Glassmaking, woodworking, metalworking, electronic, and construction industries can use them for cleaning in their manufacturing processes.

Strip Brushes

Strip brushes are used individually or in groups. The monofilament material is filled and clamped into the metal backing. Interestingly, you can customize monofilaments by material type, density, and trim length. The filaments are usually highly flexible and adaptable to uneven surfaces or protruding parts and objects.

You may use strip brushes for cleaning; however, they are mainly used to protect and seal spaces. They protect moving parts from wear and tear, keep out debris, and draught-proof contained areas for temperature control. You can vary the fill density and material of strip brushes according to the brush’s purpose. A denser, thicker brush fill is good for blocking odors, sound, vapors, bugs, and residue. Sparse fillings and soft bristles are ideal for dusting or gently sorting and guiding objects along a conveyor belt.

Strip brushes are used in many industries to protect machine components and block gaps in doorways, containers, or structures.

Antistatic Brushes

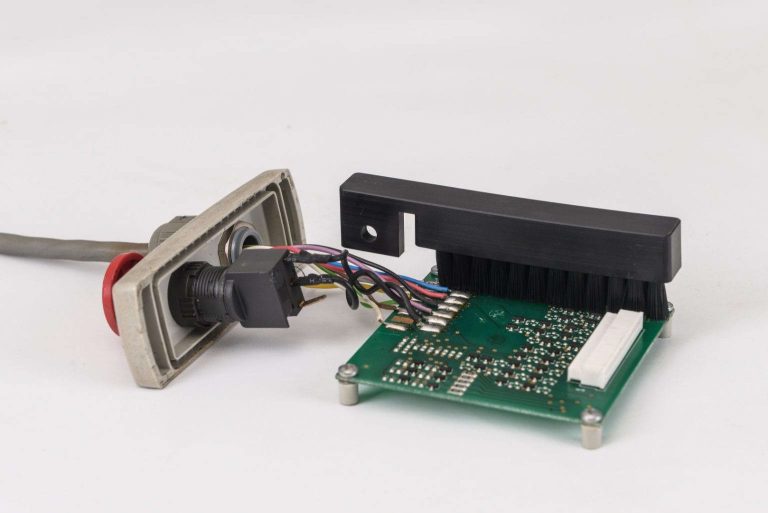

Static electricity creates uncontrolled electric shocks and surges which risks damaging the machine’s electronic components. Most industrial machines have frames that ground excess electrical charge and remove static electricity. But you can’t install solid frames on moving machine parts. Instead, you can install flexible antistatic brushes in areas where you cannot use solid frames.

Conductive, Electrostatic Discharge (ESD) or Antistatic brushes remove static electricity from industrial processing machines by creating ground connections with machine surfaces. As such, the filaments are made of electrical superconducting materials like carbon fiber, stainless steel, or antistatic nylon. Antistatic brushes have a variety of sizes and monofilament trim lengths. The kinds depend on the area size to be covered.

The electronics manufacturing industry widely uses antistatic brushes. Some industries use smaller handheld antistatic brushes for cleaning vinyl records and delicate electronic components in devices and appliances.

Forklift Sweeper

Forklift sweepers are unique and durable industrial brushes mainly used for floor cleaning and sweeping.

They are sturdy brushes that withstand heavy-duty clearing and sweeping over rough surfaces and uneven terrains. As such, they are good for cleaning areas that are tedious to hand-scrub. They can be easily attached to forklifts to clean warehouse and factory floors, roads, and yards. Use forklift sweepers to gather loose material or clear dust and waste by-products from manufacturing and treatment processes.

You can use forklift sweeper brushes indoors and outdoors for commercial, industrial, recycling, and agricultural cleaning.

Oil Brushes

Oil brushes are custom-made for oil application on objects or machine components. Yew Lee Pacific designs them to spread the oil evenly and control oil application for maintaining machinery.

You can use oil brushes in machines where oil application is automated. Oil brushes are helpful for the auto-lubrication of chains and moving parts by applying oil or grease. They also help with oiling areas that are hard to reach. It controls the oil application and spreads it evenly over objects or components.

Many industries can install oil brushes in machinery that uses automated oil applications.

Custom-Made Brushes

You may require highly customized specifications in brush manufacturing if you cannot use standard industrial brushes on your machines. Yew Lee Pacific can produce custom-made quality brushes according to your requirements and needs. You can also pick a custom design and choose materials, trim lengths, size, and fill density. Yew Lee Pacific can produce set brushes specially customized for your entire machine.

Choose Quality Industrial Brushes From An Experienced Brush Manufacturer

Yew Lee Pacific makes customized brushes and repairs them according to your needs and specifications. You may choose your brush size, trim length, monofilament material and fill density. Complete the form on our online website, and we’ll contact you to understand your requirements.

Choosing a higher-quality brush that fits your machinery and manufacturing processes is crucial. Using a well-fitted brush will also ensure your machine operators’ safety and the machinery’s durability. However, finding a regular brush that meets all your needs can take time and effort. Choose custom-made industrial brushes to create a smooth manufacturing and cleaning process for your business.